ARENA AIRCON

Arena Air Conditioning; Stainless AHU Build

Ductless Air Distribution; Factory Aircon

page 1 of 2

Factory Arena Aircon

Dove Thermal designs and builds ductless aircon systems for low cost climate control in new and existing distribution warehouses, factories, public buildings and long-term chilled storage sheds. They exploit boundary layer attachment for perfect air distribution without recourse to overhead duct systems or equipment. In addition to providing accurate and economical large space airconditioning our systems achieve significant heating cost reduction during winter months whilst continuing to assure set point control of temperature and humidity. Their effectiveness and value-for-money derive from simplicity in the design and construction of our stainless steel air handling units, optimized capital and operating costs, and our award-winning record in thermal engineering and project management.

Capability to recover from transient inleakages, air filtration for the capture of FLT tyre dust, and assured levels of relative humidity below 70% for protection of cardboard packaging are specific features. Our ductless aircon systems for factory and warehouse airconditioning minimize use of automatic valves and dampers through inverter control of pumps and fans, and the thyristor drive of heating elements. This approach optimizes operating economy, simplifies operation and entails minimal maintenance. While direct expansion air handling units are preferred for smaller layouts and remote distribution points, larger installations may circulate heat transfer fluid through local air handlers supplied by a central chiller installation.

Building Layout

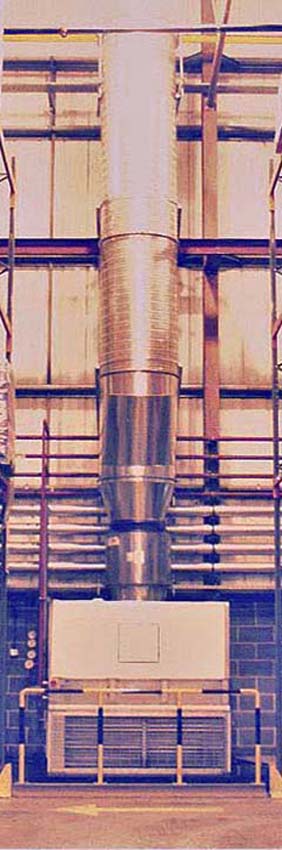

Building & racking layout are used to channel air distribution and obviate transmission ductwork. Our stainless air handling units are ideal for warehouse airconditioning: they exploit boundary layer attachment of return airflows for ductless air distribution throughout buildings exceeding 50 metres length. Illustrated is one of seven warehouse aircon units pulling from the roofspace of a portal-frame shed, and delivering its conditioned discharge into a facing aisle. Operating on a similar basis, Dove Thermal’s stainless steel factory airconditioning units are designed to complement state-of-the-art manufacturing and services environments.