HTF & HOT OIL LIQUID PHASE HEATING

Electric HTF Heaters

Thermal Fluid Heating Processes

Hot Oil System Inspection and Service

HTF & Hot Oil Heating Plant Maintenance

Operational Parameters

HTF and hot oil systems can be worked either side of atmospheric pressure, although pressurised installations allowing operation above their normal saturation temperatures are more complex than for steam - partly through need to inhibit oxidation of the working medium. Even so, a synthetic HTF or thermal oil heater can run at 300 deg.C under normal pressure, whilst saturation pressure for dry steam at that temperature is around 85 barg. No thermodynamic pressure is induced where the fluid vapour pressure remains below atmospheric, and engineering costs are much-reduced if systems are to operate only under gravity head.

Thermal Fluid Heaters

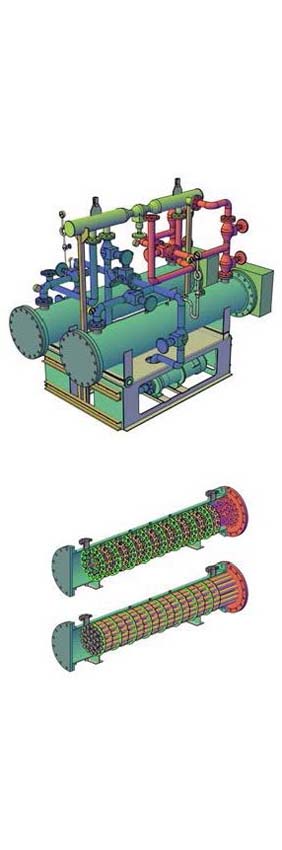

Dove Thermal Engineering has built fired- and unfired plant & equipment for Therminol and Dowtherm thermal fluid and Shell Thermia hot oil systems. We have successfully worked Solutia T66 at temperatures to 340 deg.C under atmospheric pressure - as for our Klieverik thermo-bonding calendering machine installation (see Gallery page). The isometric shows a modularized pair of electric calorifiers.

HTF & Hot Oil System Service and Repair

Heat transfer oils and synthetic fluids deteriorate with time - whether by oxidation, or through thermal cracking of their molecular structure. Oxidation occurs unless expansion vessel contents are nitrogen blanketed - or otherwise, in the absence of measures inhibiting the affects of exposure to atmospheric air. Their stability is dependent upon working temperature, operational profiles, and system design. Carbonization onto the inside walls of heater tubes, and associated sludge entrainment in the recirculating fluid progressively act to deteriorate heat transfer performance and increase risk of plant failure. We provide inspection and maintenance services for systems and working fluids, to protect heating plants and the production equipment in circuit with them.

Typical Capacity and Workscope:

Liquid Phase Heating Plant for International Automotive Components

Electric thermal oil heater installation for Sigma Technologies

Multiple HPHW and LPHW Heating Installations and Systems

Pressurized HTF Plant Rectification for Midland Oil Refinery

Thermal Fluid Heating Plant for Tiflex Limited

HTF heating plant & equipment for Flint Ink