DIRECTORY

ABOUT

GALLERY

HOME

CONTACT

Liquid Phase HTF and Hot Oil Heating Plant Design

Dove Thermal Engineering has designed and built unblanketed Thermia B systems for hot oil heating at 290 deg.C using conventional hot oil boilers, Therminol 66 thermal fluid process heating installations working to 340 deg.C at atmospheric pressure, and re-engineered Dowtherm A installations running at 370 deg.C and 6.7 bar(g). Click here for photos and stress isometrics of pressurised and gravity head circuits.

Solid State Thermal Appliances

Thermo-electric devices allow unique heating and cooling design opportunities for compact applications – particularly in aerospace and electronic environments. Consumer Products we have prototyped and developed include a table-top wine cooler, a chill box with freezer compartment, an immersion cooler, cooling jug and various machine coolers.

Cooling Process

We apply the maths – and practice - of heat transfer & fluid mechanics to all types of process cooling plant design projects. Accurate modelling enables "right first time" results in the design and construction of (for instance) batch and batch-continuous cooling plant and equipment, with accurate prediction of processing times.

Heating Process

Many of the reverse flame heaters now firing industry-standard continuous baking ovens are of our original design, while more recent work includes plant and equipment for hot box buffer storage, pressurized HTF systems and biomass autoclaving processes. We have designed and installed several boilerhouses and steam heating plants driving a variety of manufacturing operations, where isothermal operations offer significant advantages over sensible heating mechanisms.

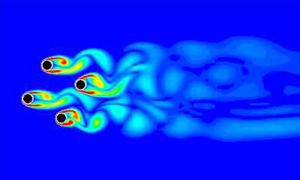

Heat Transfer & Fluid Mechanics

Effective heating and cooling design starts with a clear understanding of the host operation and its behaviour.

This page reviews how the fundamentals of heat-and-mass transfer underly all natural and man-made operations. Following from our design and construction of host systems, we develop working profiles to match duty conditions and originate specialist heat exchange plant aimed directly at process improvement.

Providing forensic and expert witness services in heat transmission and related fields draws directly upon our experience as thermal designers and consultants. Our mainstream engineering activities span a broad range of technologies, including airframe and engine systems test rigs, biothermal plant and processes, and NDT methods for structural and systems inspection. We originate equipment and procedures for new product development, process enhancement and in support of our own undertakings.

Dove Thermal Engineering Limited, Uttoxeter, ST14 8QX

Telephone: 01889 569933