DIRECTORY

ABOUT

GALLERY

HOME

CONTACT

Plant & Equipment

Dove Thermal specialize in the design and production of thermal plant, processes and machinery, and serve as consulting engineer for new & pre-existing works. Where necessary, we can help in drawing-up the Terms of Reference framework and URS for a prospective project, supported by a Gantt-charted management plan setting out agreed objectives and timescales. Our background in providing engineering design services at all levels guarantees successful completion of the project in hand.

Factory Services

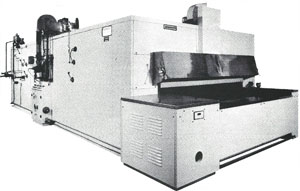

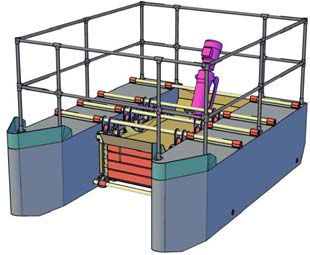

Having undertaken over fifty factory services projects as thermal engineering consultants and main contractors - and delivered a similar number of technical product designs for clients throughout the U.K. - Dove Thermal has the necessary experience and capability to resolve problems across a range of manufacturing and product engineering processes. We have been engaged as heating consultant and cooling experts for all aspects of HVRAC applications, combustion, heat transmission and fluid systems operations. Examples include design of thermal oxidizer and recuperator stages for Stein-Atkinson-Stordy, pipeline drying plant for Chorley Engineering, and reverse-flame heating stages for the Spooner-Vicars (Sasib) range of JetMass tunnel ovens (below)

Biothermal Plant & Equipment

Dove Thermal has investigated autoclaving techniques for the steam and dry gas explosion of ligneous and herbaceous material, and originated process support equipment for biomass drying, syngas processing and hydrolization. Our high speed thermodynamic valves for accelerated steam explosion and blow-off have radically improved food processing techniques. We have designed and built several wood waste heating plants, and undertake commissions as heating experts for new project development. Upon completion, we help our clients to register with the Renewable Heat Incentive (RHI) and gain self-supplier status on the Biomass Suppliers List (BSL).

Environmental Engineering

Dove Thermal innovations in noise and vibration control include the reactive mass balancing of rotating machinery, control of machine noise and vibration, and architectural acoustic doors tuned to attenuate specific sound frequencies. We also undertake - and resolve issues arising from - Plant Noise Surveys, Environmental Noise Measurement programmes, and represent client companies involved in planning reviews and public enquiries. Our environmental engineering activities include consult-design-construct projects for controlling boiler stack emissions, dyehouse effluent treatment and oil lake recovery equipment (above)

Our Credentials

With over 30 years’ experience in high-level thermal consultancy, we provide resources corresponding with those formerly available through the DTI's Manufacturing and Design Advisory Services operated by the Production Engineering Research Association (PERA) and the Design Council respectively. We received a Design Council award for “Consistent High Standards of Project Management and Design Capability” as its long-term provider of engineering design services for thermally-related products, plant and systems.

Design & stresswork for polymer conversion plant running Dowtherm A at 360 deg.C, 6 bar(a)

Prototyping and development of solid state dynamic balancing system for large Rotary Dyers

200 kW gas-fired liquid phase plant, running Therminol 66 to 340 deg.C at normal pressure

260 kW MDF waste fired heating plant with waste material storage and handling equipment

85 kW base load chiller plant, with process management augmenter set

Factory fit-out and services for production of 14.4 tonne/day cube ice

Thermal design consultants to Tate & Lyle Sugars’ Silvertown Refinery

Steam turbine and equipment for National Maritime College, Cork RoI

Air Rings for blown film extrusion (demonstrated at Interplas)

Variable Concentration Batch Heating for Ad-Blue production

Warehouse air conditioning plant, rated 575 kW at 7 deg.C

Process plant design of packaged polymer quench plant

New-build Boiler Plant Rectification

Biomass boiler plant consultancy

Rotary sample dyeing machine

Dyeworks process plant design

Links to related pages:

Pipework Design & Pipefitting Service

Consulting Project Engineers

Plant Design and Operations

Works Engineering

Dove Thermal Products

Shell-and-Tube Heat Exchangers

Coolant Management Modules

Packaged Plant Skid Mounts

Balance-of-Plant Modules

Steam-Heated Calorifiers

Packaged Quench Plants

Thermal Fluid Heaters

HTF-Heated Calandria

Thermal Oil Heaters

Air Handling Units

Cooling Tunnels

Drying Tunnels

HTF Heaters

Dove Thermal Services

Consult-Design-Construct Services

Thermal Engineering Consultancy

Process Plant & Process Design

Thermal Fluid Heating Systems

Environmental Systems Design

Testing & Proof of Concept

Forensic Engineering

HVRAC Engineering

Dove Thermal Engineering Limited, P.O.Box 5, Uttoxeter, ST14 8QX

Telephone: 01889 569933

Click here to send e-mail